Let's Search

Let's Search

menu

close

Website Design Copyright 2026 © 捷弘國際貿易有限公司

All Rights Reserved. 網頁設計 by 覺醒設計

The traditional dyeing and finishing process is not environmentally friendly, resulting in large-scale water pollution and waste. These are the environmental costs of textile manufacturing. Therefore, "waterless dyeing" has become the most important green indicator in the environmentally friendly textile market!

Polymer waterless dyeing fabric technology is an independent innovative research and development new patented technology with energy conservation, environmental protection and process optimization as the main core. It is an important trend in today's textile market! Waterless dyeing is to reduce water consumption from the source during the dyeing process, thereby reducing the amount of dye usage, chemical usage, heat energy emissions and wastewater emissions. While shortening the process, it also breaks through the physical properties of traditional dyeing process products and is in line with truly waterless dyeing. Environmental protection requirements for dyeing.

(Trends in the environmentally friendly textile market|enunic waterless dyeing technology)

Jiehong Textile has 40 years of experience in the textile industry. Adhering to the concepts of sustainable management and environmental protection, it has invested in "polymer waterless dyeing technology" for nearly 10 years, and established the enunic brand for stable mass production for 6 years. In order to meet the market demand for environmentally friendly fabrics from major brands, enunic has established a new Vietnam factory for R&D and manufacturing.

Enunic's production process has passed the BSI Royal Standards Institute water footprint verification and greenhouse gas emission inventory. It adopts strict international standards to examine the water-saving capabilities of enunic's polymer waterless dyeing technology and its expectations for green textiles. It has been revealed through BSI's verification The impact of products on the environment reduces the burden on the environment and thereby achieves the sustainability of the earth's ecology.

(Environmental textile-related certification|enunic waterless dyeing technology)

enunic has established a professional R&D team, introduced advanced textile dyeing technology at home and abroad, and focused on researching the improvement of waterless dyeing technology. After 8 years of continuous technological upgrading and transformation, it has solved many impacts on equipment, processes, testing, products, etc. Key technical issues in production.

enunic not only reduces water consumption from the source during the dyeing process, but also directly reduces the amount of dye usage, chemical usage, heat energy emissions and wastewater emissions, etc., complying with the environmental protection requirements of truly waterless dyeing.

enunic uses trustworthy environmentally friendly raw materials and uses a polymer water-free dyeing process to improve the dye leveling power and react quickly with fibers, allowing small dye molecules to quickly absorb and evenly adhere to the bottom layer of the fiber. The chemical bond between the dye and the fiber is very stable, thereby inhibiting dye detachment and fading, and achieving higher physical property standards.

enunic exerted its innovative spirit and actively overcame various difficulties and challenges, and finally successfully independently developed dyeing equipment for the polymer waterless dyeing process. This exclusive design has obtained a nationally authorized invention patent and has complete independent intellectual property rights. It provides textile dyeing production The feasibility of greening and anhydration builds strong support.

enunic attaches great importance to the quality and efficiency of color printing, and develops the best and most suitable products according to customer standards in the shortest possible time. Different from traditional color printing, enunic laboratory color printing sample size can be the same as A4 size, and cloth samples can be quickly provided to customers for reference and increase the color matching rate of mass production. The laboratory coloring equipment simulates the mass production machine, improving the reproducibility of the laboratory to on-site coloring, and the color accuracy reaches more than 95%.

The biggest feature of enunic is the use of advanced "one machine, multiple bodies", which allows dyeing, drying and styling to be completed at one time. There is no need to use a single machine for drying and styling, and there is no need for the complicated process of traditional dyeing, thus saving a lot of labor and time. Adding functional formulas during the dyeing and finishing process can shorten the process time and reduce wastage to a great extent, and also avoid color changes caused by back-end processing, which will affect the color matching rate.

The enunic polymer water-free process has fast coloring speed and can be dyed in one go. The affinity between the fiber and the dye allows the color molecules to be directly adsorbed to the bottom layer of the material fiber. As a result, the color quickly transfers and adheres to the textile material, allowing the fiber to have superior color development, allowing the bright colors to not fade, and the colors to radiate bright colors from the inside out. It not only breaks through the limitations of fluorescent colors in cotton dyeing, but also breaks the color restrictions of cloth samples of various materials, breaking through 98% of dyeing colors.

The enunic dyeing process is completely free of water and environmental pollution. The original polymer water-free dyeing process does not use a high-pressure production environment, thus ensuring employee production safety. The production process strictly implements safety management institutionalization and production standardization. The enunic series of products have been tested and certified by international authoritative organizations and are free of carcinogenic amine dyes and harmful substances to the environment and human health. The products are safe and non-toxic, meet the requirements of world brands, and provide consumers with safety and quality assurance.

enunic combines the ability to optimize equipment, use mature technology, execute production management capabilities, and train operators to achieve stable production capacity. One piece of equipment can produce up to 35 meters per minute, making the polymer waterless dyeing process used by enunic the only new green waterless dyeing and finishing technology in the world that can achieve mass production and is widely used. At the same time, it also changes the concept that environmental protection equals expensiveness, and creates value for customers with the lowest production cost and the most convenient production method.

enunic has passed BSI ISO9001 management system certification and has a complete quality control process. From raw material inspection to online product quality management and final finished products, we check every step of the way. enunic's waterless dyeing fabric process is also working towards standardization, automation, dataization and intelligence, and stabilizing standard formulas, standard processes and standard processes. The polymer water-free dyeing process can avoid the color difference before, during and after traditional dyeing, and ensures that the color is evenly dyed and penetrates the fabric. It not only dyes beautifully, but also has the advantages of a high-quality product with excellent fastness and excellent physical properties.

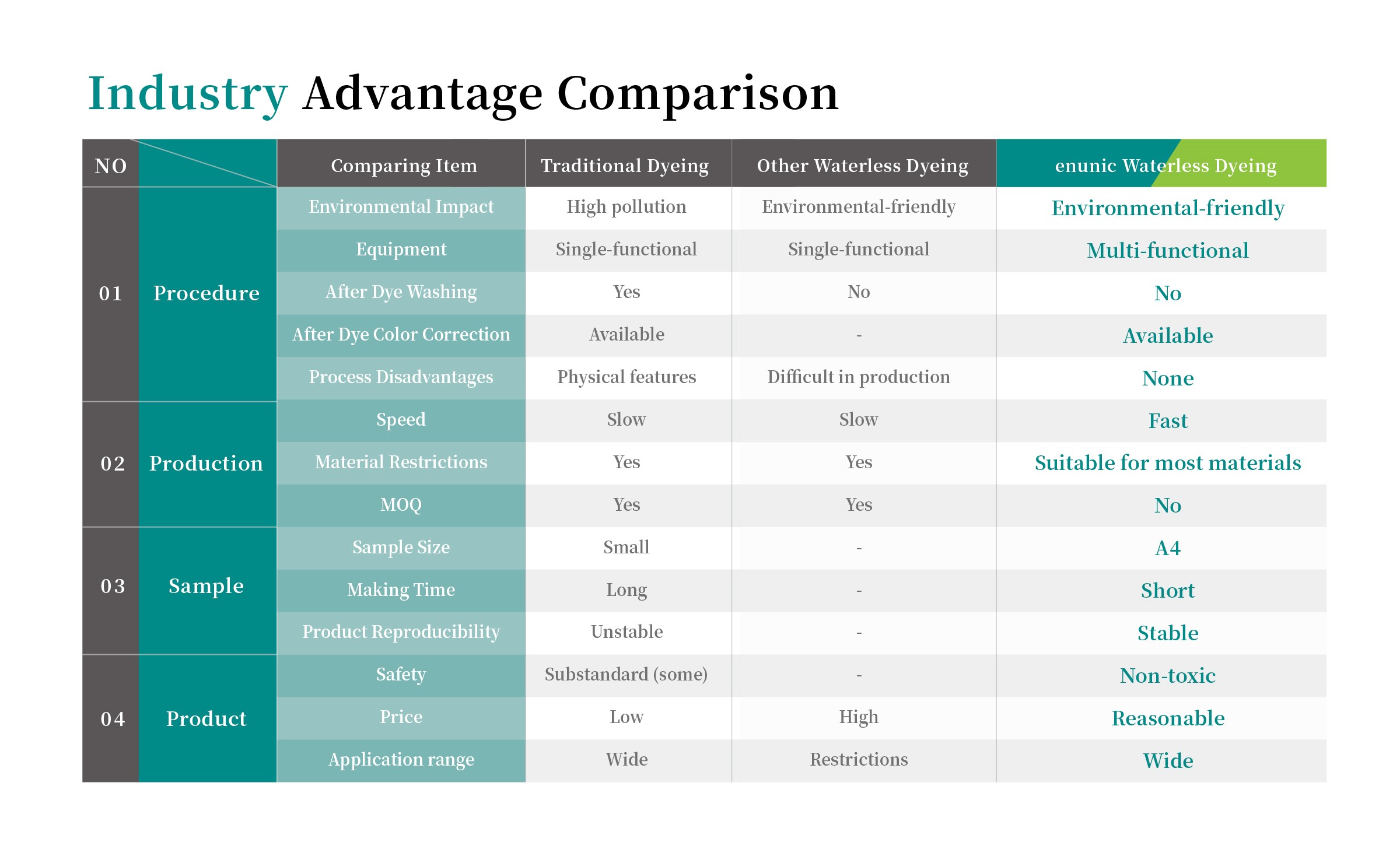

(Comparison chart of advantages in the environmentally friendly textile industry|enunic waterless dyeing technology)

enunic polymer waterless dyeing has successfully achieved breakthroughs in the field of technology research and development and product mass production stability. The R&D center can expand into different fields based on material-related characteristics and further improve customized services based on customer needs.

enunic will provide environmentally friendly, energy-saving and efficient dyeing processes for the textile dyeing industry. And constantly achieving outstanding innovation and transcendence, Jiehong Textile has been moving forward, firmly moving towards green and environmentally friendly dyeing processes, and cherishing the dream of green industry.

On the road of sustainable and environmentally friendly textiles, we never stop, we take great strides forward, and continue to stage a new future of environmentally friendly and sustainable dreams!

We use cookies to collect and analyze information on site performance and usage. By Clicking "Continue" or by clicking into any content on this site, you agree to allow cookies to be placed. To find out more, please visit our privacy policy。

CONTINUE GO TOP

GO TOP